- EMAIL: SALES@CRESSALL.COM

- • TEL: +44 (0) 116 273 3633

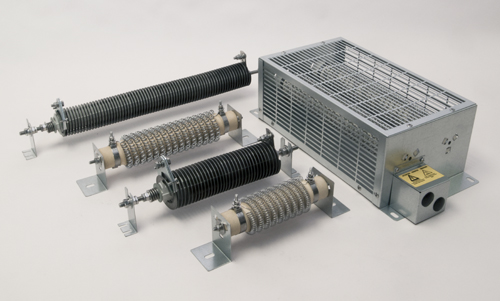

DYNAMIC BRAKING RESISTORS

ADVANTAGES OF ELECTRIC BRAKING

An important benefit from using an electric drive is that reliable systems of regenerative and dynamic braking resistors are available to complement or replace traditional mechanical braking systems. The advantages of electric braking include control, reliability, mechanical simplicity, weight saving and in some cases the opportunity to make use of the regenerated braking energy.

When electric motor driven machinery is stopped energy is created, which can be regenerated into the drive system through the motor itself acting as a generator. This braking energy needs either to be put back into the power supply or dissipated as heat.

An external dynamic braking resistor (DBR) provides a compact, cost effective method of controlling the braking, absorbing the energy and dissipating this as energy as heat.

Cressall manufactures DBRs for any application, with power ratings from a few watts up to many megawatts and with any duty cycle.

- Suitable for any power rating and duty cycle

- Suitable for any make of drive

- Standard or custom designed

- Compact and economical standard range

- Complete enclosed solutions or open assemblies for installation flexibility

CUSTOM DYNAMIC BRAKING RESISTORS

For continuous powers of more than 100kW, for medium/high voltage use, with fan or water cooling or for use in specialist applications such as marine, mining etc we can design custom resistors to your specification.

Previous designs include:

- 800kW continuously rated fan cooled, 316 stainless steel, deck-mounted for pipe laying vessels.

- 1.0MW continuously rated fresh water-cooled for winch braking.

- 1.5MW continuously rated naturally cooled, silent operation, for use on the third rail of a metro system.

- 15MJ air to water cooled IP56 closed loop unit for hazardous environments.

STANDARD DBRs FOR UP TO 100kW CONTINUOUS POWER

Continuous powers up to 25kW, braking power up to 250kW

Cressall ES and DBR range of high capacity DBRs for regenerative braking are low cost, easy to specify, quick to install and with ratings to suit most commonly supplied inverter drives.

Units can be supplied either from stock (click for our distributors) or can be manufactured within a few days.

Continuous powers to 100kW, braking power up to 1MW

Cressall Expanded Mesh and Stamped Grid DBRs are suitable for continuous powers to 100kW. They are manufactured to order but built to a standard design and can be supplied with short lead times. Enclosure degree of protection can be IP20 or 23; materials are usually 304 or 316-grade stainless steel, but can be painted or galvanized mild steel if required.